Designing a Hot Wheels car with Polestar DNA that looks great and works well in the Hot Wheels’ track system.

In 2024, I entered the Polestar Design Contest, a competition that challenges automotive designers to build upon Polestar’s modern electric vehicle design language.

The theme for the year was a collaboration with Hot Wheels, asking designers to imagine a Hot Wheels collectible inspired by Polestar, with no limits except the requirement to be manufacturable at a 1:64 scale.

The Challenge: Designing a Hot Wheels Car that Defies Boundaries

The design brief encouraged participants to dream big and deliver something thrilling and imaginative.

While competing against automotive design students and professionals from around the world, I approached the challenge with a clear vision: to design a low, sporty hypercar that would perform on Hot Wheels tracks, handling loops, launchers, and banked turns.

Concept Development: Bridging Imagination and Functionality

I would need to leverage my industrial design expertise and an understanding of manufacturability to stand out from the automotive design professionals. I was not going to beat them on aesthetics and sculpture, but I could win by making judges see how this concept could easily become a mass-produced Hot Wheels car.

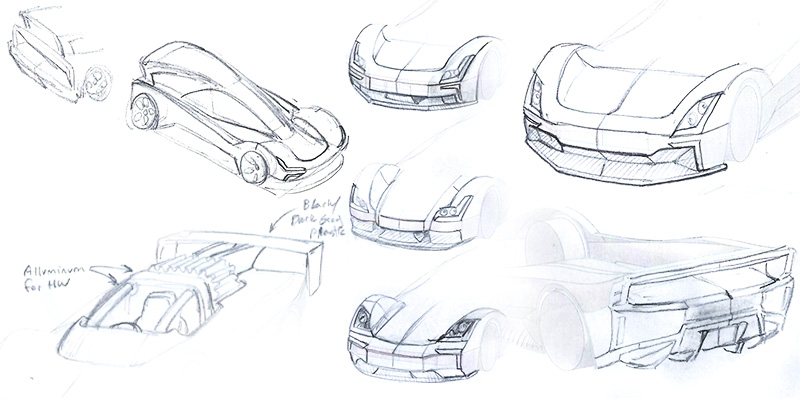

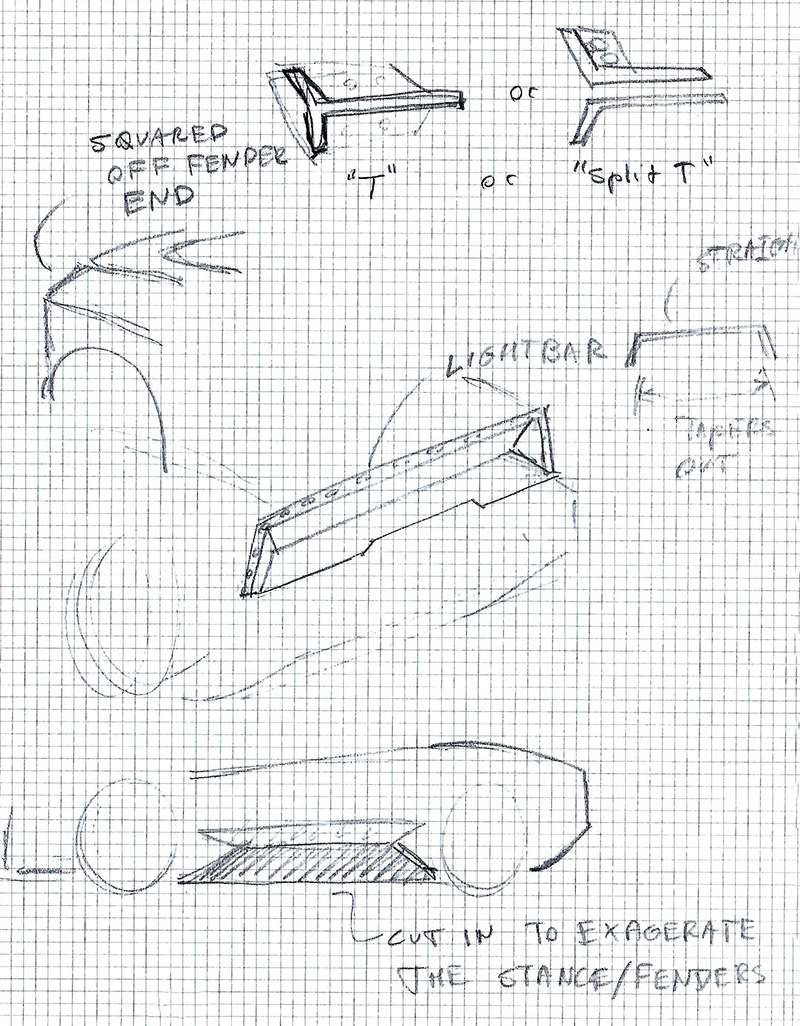

I sketched a variety of thumbnail concepts. I also leveraged an AI image generation tool (DALL-E) to assist in brainstorming.

My 9-year-old son’s Ferrari 333 Hot Wheels car inspired me during this phase, combining the visual dynamism and track performance I aimed to replicate.

Leaning on My Strengths: Manufacturability

Given that I was competing against specialized automotive designers, I focused on ensuring the design could easily transition from concept to reality—a hallmark of my industrial design approach. I always say that a good idea that can’t be implemented is not a good idea at all.

Hot Wheels are traditionally made in layers aligned by two posts and melted so the layers never come apart. No different, my design was composed of three distinct layers:

- A gloss black plastic base

- A silver plastic middle layer

- A die-cast metal top layer

I also minimized labor-intensive hand painting by strategically using white for the front headlights and red for the rear, limiting paint application to protruding elements.

Capturing the Polestar Design Language

To make the design distinctly Polestar, I incorporated key elements of the brand’s design DNA.

The headlight shape, the side cavities, and the rear light bar are all tributes to Polestar’s iconic design language, especially inspired by the Polestar 6 concept car.

These elements were blended with the sleek, futuristic aesthetics expected of a Hot Wheels vehicle, balancing fantasy with real-world brand recognition.

3D Modeling and Rendering

Using SolidWorks 2024, I modeled the entire car, which was no easy feat. Thankfully, I am an expert in 3D modeling with Solidworks.

Advanced surface modeling tools allowed me to create a hypercar shape with dramatic curves, and I ensured that all layers and materials would fit together seamlessly.

I then rendered the design in SolidWorks Visualize 2024, placing it in a dynamic Hot Wheels track setting for my final presentation.

A Dream Realized: The Circuit Charger

The last element of the design was the name. I used AI again (ChatGPT this time) to brainstorm a long list of cool names. I chose ‘Circuit Charger’ because it was a double entendre hinting at both charging around a race circuit and a charging circuit being an electric car.

Although I did not make it to the finals, this project remains one of my most fulfilling. It combined my love for Hot Wheels with the challenge of translating Polestar’s cutting-edge aesthetics into a collectible toy.

Designing the Circuit Charger was a dream come true, blending imaginative design with practical manufacturability.

Leave a Reply