A visually engaging and confidence inspiring demo display that raised the sales of eBikes.

Client: Canadian Tire Corporation

Brands: Diamondback and Raleigh

Retailer: Canadian Tire

Objective: Create a light, easier‑to‑assemble, and visually engaging eBike demo platform with off‑season storage and adaptability for bicycles with different wheelbases.

Role: concept design, visualization, industrial design, design for manufacturing, technical drawing, quality control, package design.

Materials: Steel sheet metal and plate, magnetic sheet, hardware.

Manufacturing Processes: Laser cutting, CNC brake bending, welding, metal fabrication, digital printing.

Key Challenges: Wrapping platform around roller trainer without interference, intuitive assembly, keeping weight low while supporting 350+ lbs, breaking down for shipping and storage.

Outcome: Units produced for stores across Ontario and Quebec stores; easy setup by staff, became focal point of sales floor, strong dealer and customer engagement

Client

Canadian Tire Corporation approached the Central Group while I was an industrial designer there.

The Challenge

The merchandising manager and category manager knew that they could sell more eBikes (electrically assisted bicycles) if people could just feel the boost in power you get when you press down the throttle of the electrical assist motor.

But letting customers ride a boosted bike around the sales floor would be a disaster waiting to happen! They knew they could use a roller trainer but wanted to make it easier to step up into and attract shoppers with graphics branded to the bike on display.

Objectives

- Platform to support as much or more weight than the bike and roller trainer (350 lbs+)

- Off‑season storage solution

- Adaptable to a range of bike wheelbases

- Visually inviting

- Replaceable graphics

Scope of Work

- Met with client and discussed requirements for an in‑store eBike demo platform, including weight, footprint, and seasonal storage needs.

- Wrote project brief

- Developed multiple concept directions (floor graphic, platform, and platform with graphic surround.)

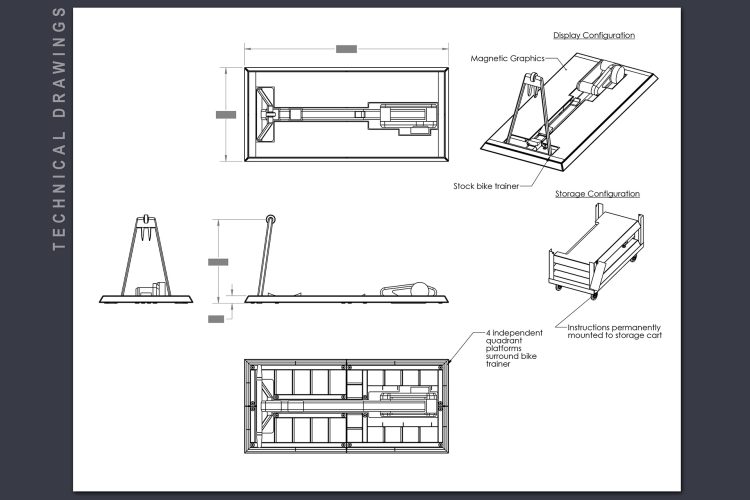

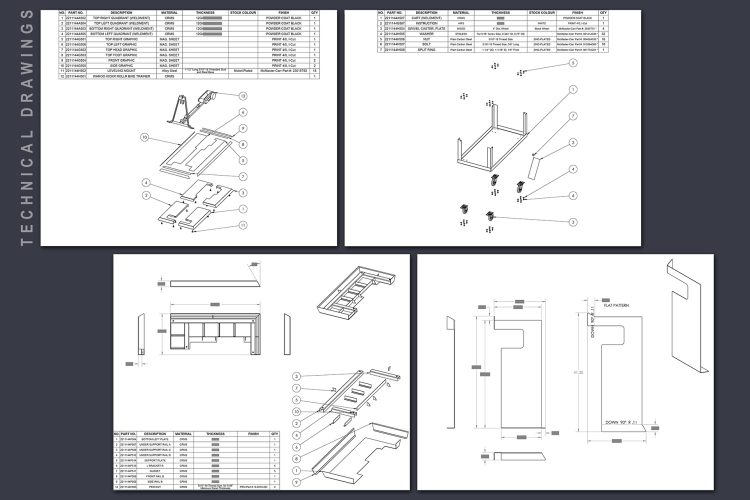

- I used Solidworks to create detailed CAD models and technical drawings.

- Specified manufacturing methods and finishes.

- Worked with fabricators to create prototype.

- Presented prototype to stakeholders.

- Packaged prototype to travel to dealer show.

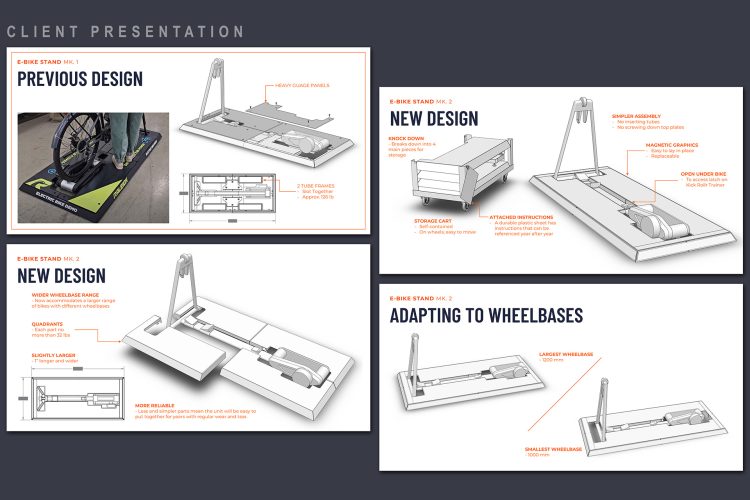

- Reengineered the design to accommodate the new features and requirements based on the feedback from the client and their stakeholders.

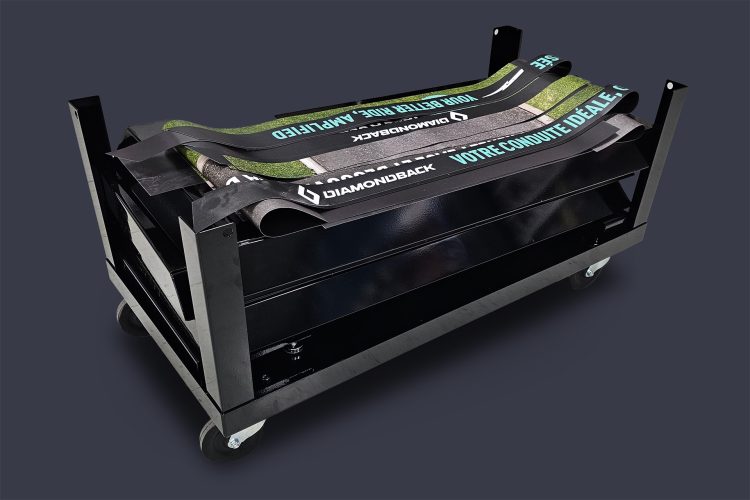

- Designed a custom storage cart with casters and a permanently attached instruction sheet for off‑season storage and reassembly.

- Collaborated with internal teams for production graphics, renderings, estimating, and instruction design.

- Coordinated with suppliers to ensure quality control, suitable packaging, and on‑time delivery to stores.

- Presented prototypes and “first‑off” production units to Canadian Tire stakeholders for approval.

- Oversaw final production run for deployment in Ontario and Quebec stores.

Key Innovations

- Breaking the platform up into 4 quadrants as to:

- Have no part heavier than 35 lbs so any person could safely move it

- Assemble around the roller trainer without interference.

- Create a seamless look by spanning the magnetic graphics across the platform.

- Create a storage cart with permanent instructions as to:

- Easily store the unit between seasons

- Clearly mark the display as being owned by Canadian Tire Corporation

- Refamiliarize staff on how to assemble the display at the beginning of each biking season.

Materials & Manufacturing

- Materials: Steel sheet metal and plate, magnetic sheet, hardware

- Processes: Laser cutting, CNC brake bending, welding, metal fabrication, digital print

- Finish: Black powder coat, 4‑colour printed graphics

Design Challenges

- Wrapping around the roller trainer without interference: The platform needed to fully surround the trainer and bike while leaving just enough clearance to avoid contact with the static and moving parts during a ride.

- Balancing light weight with high load capacity: Each quadrant had to be under 30 lbs for safe handling, yet the assembled platform needed to support riders of 350+ lbs without flexing or instability.

- Breaking down for shipping and storage: The design had to disassemble into compact, manageable parts that could be shipped economically and stored in the store’s back room between seasons.

- Ensuring intuitive assembly in‑store: Store staff with no technical background needed to set up the platform quickly and correctly without tools based on the steps on the instruction sheet permanently attached to the storage cart.

- Integrating graphics as both branding and structure: Magnetic graphic panels concealed the hardware, lock quadrants together, and present a seamless branded surface.

- Adapting to multiple bike wheelbases: The platform geometry needed to accommodate different eBike models without modification or extra parts.

- Designing for seasonal re‑use: The solution had to survive repeated assembly/disassembly cycles without wear that would compromise safety or appearance.

Results & Impact

Canadian Tire’s merchandising manager, bike brand manager and dealers who had opted into the program were all happy with the demo platform and the presence it had in store. It allows the bicycle sales people to easily sell eBike models over a standard bike, which is a 40% upsell.